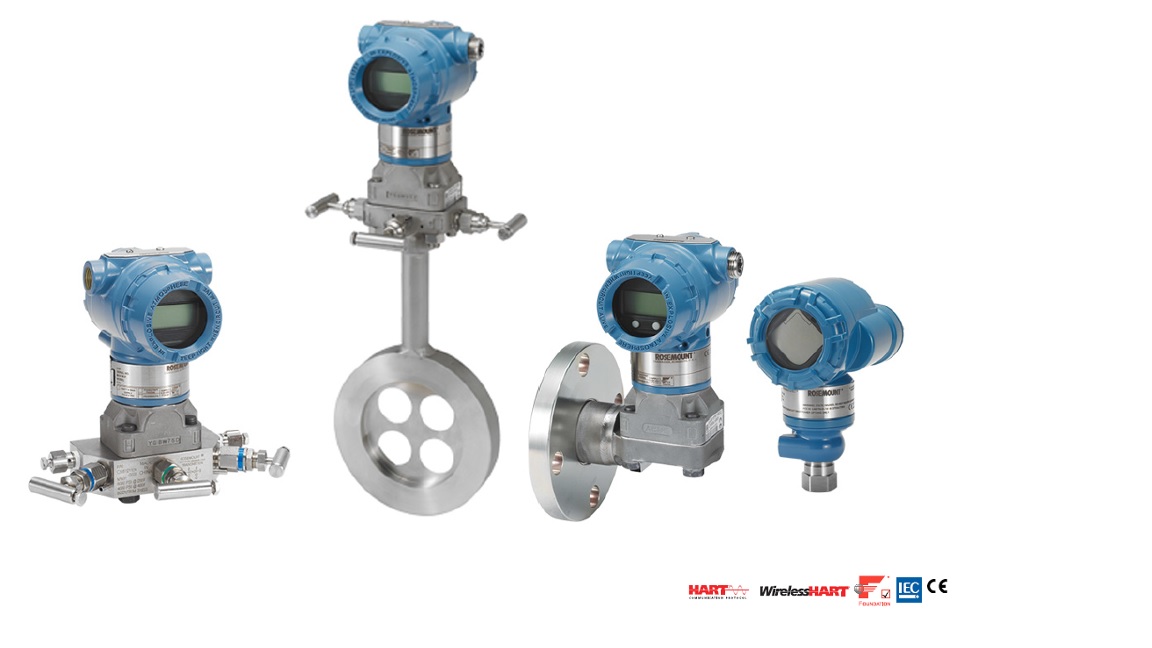

A Rosemount Vortex flow meter operates similarly to other vortex flow meters on the market. However, the Rosemount line offers durability, accuracy, and reliability in the measurement of all types of media including steam, liquids, or gases. This versatility, as well as the ability to work in the most demanding applications with limited maintenance or repair requirements, make these flow meters a top choice for many engineers.

The Advantages

One of the key factors in choosing a Rosemount Vortex flow meter is the design. This is a flow meter that is able to detect changes in the flow of the media without the need for moving parts. Without moving parts there is limited need for repairs on these components and, in addition, they have a longer life cycle.

Once installed, these are flow metering options that rarely leak. The installation process is also very simple and streamlined, and there is no need for additional lines, which also helps to reduce the risk of leads and installation complications.

The Measurement Process

The operation of the Rosemount Vortex flow meter is uncomplicated but very accurate. The fluid or media makes contact with a shedder bar, which is a form of obstruction that is permanently mounted in the meter. As the media hits the shedder bar, it forms different pockets of pressure that are captured by the sensors. This is done by the change in pressure causes a small element to vibrate or oscillate at a particular frequency. Changes the oscillation are recorded as changes in pressure and passed from the sensor to the transmitter.

The choice of the Rosemount models of vortex flow meters can be used to measure both temperature and flow. They will adjust automatically to changes in the density of the media, which allows for correct data capture and transmission, even in superheated steam applications or for any types of liquids and gases.