It may seem that after all the decades of manufacturing and designing of different custom extrusions that there has to be a die manufactured for any possible component. While many companies have thousands of dies and access to thousands more through profession networks, the demand for custom parts continues to grow.

Companies that are custom aluminum extruders are constantly asked to create new custom extrusions. Most of these are for prototype components that will then go into general manufacturing. Other demands can be for retro parts and components where the original die are no longer available or perhaps the part was fabricated and not extruded.

The Scope

Typically for a single prototype part where production will be limited or perhaps years in the future, using aluminum extruders to create a custom die may not be cost effective. However, this is only under very specific circumstances that are unique to some industries.

On the other hand, it makes sense to choose to produce a custom die with a top aluminum extruding company if the prototype will soon go into production or if production is likely. This saves the cost of trying to manufacture the part through a metal fabrication company for the first few runs and then moving to custom extrusion to produce the part in the future.

The Complexity

It will be important for a company to compare the cost of fabricating and machining the part as compared to using aluminum extruders. Remember that with machining there will be an additional waste component that is not present with extruding, plus machining tends to take longer and to be more cost ineffective for large numbers of parts and components.

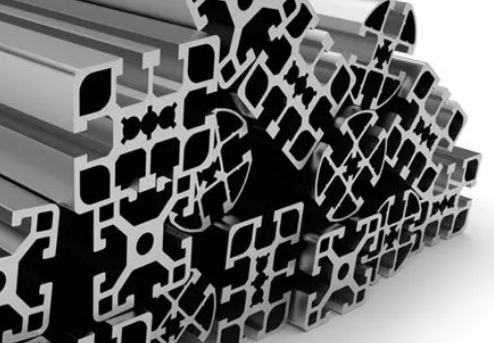

With the development of new extruding processes, even very complex designs can be completed over and over again with absolute adherence to the tightest tolerances. Trying to manufacture and machine the parts, even with CNC technology, is more likely to result in slight variations that may be impossible to detect with the human eye. In some applications, even those virtually invisible variables can be problematic, which is why many fabrication and manufacturing companies choose custom extrusion over machining options.

Finally, the speed of producing extruded parts is superior to that of machining. Large run orders can typically be produced in very short turnaround times by extruding companies, making this a great option for manufacturers and fabricators of all sizes and in all industries.