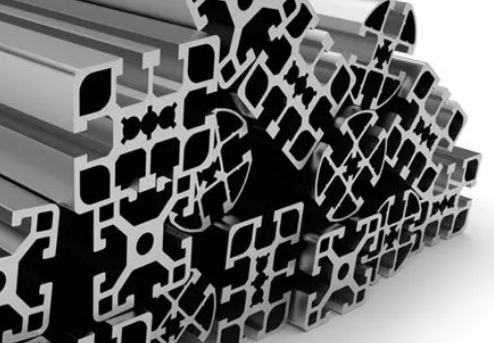

Working with a company with years of experience in producing aluminum extrusions is always the best option if you are considering a custom design. This is not a simple process and there are many different factors to consider when developing the final shape.

First, it is important to realize that just because custom aluminum extrusions can be made, it doesn’t mean that they will necessarily produce the component you need. The shape, the different thickness and the design itself can all have inherent problems that will make it ineffective to use for the project or the fabrication.

The engineer designing custom aluminum extrusions can provide information, advice and troubleshooting tips on potential problems that can occur with some specifications or design elements. This help can be a very big cost savings as the creation of a die can be thousands of dollars even before production of the extrusion begins.

Keep it Simple

The fewer differences in shapes and elements in a design the lower the cost of the production of the die will be. It is also easier to design a die with all components having the same thickness rather than several different wall thickness that vary throughout the shape.

Additionally, think of minimizing the needs for cavities and other types of more complicated shapes such as channels. There more voids or hollow areas in the die the less strength the final design will exhibit.

Watch the Angles

If you look carefully at many custom aluminum extrusions, you will notice that the corners of shapes or elements in the profile are typically rounded just slightly. The extrusion process, forcing semi-liquid aluminum through the die, is much more efficient with slightly rounded lines or corners rather than sharp angles.

Consider Your Options

While this may have been better as the first item on the list, it is worth your time to talk to the design technician or an engineer with the aluminum company. He or she may be able to suggest an option or a workaround that will allow you to use a standard extrusion for your design.

This will not only save money, but it will also make supplying the standard extrusion in a very short lead time a very simple task. With the custom extrusion option, the time between developing the die and actual delivery of your custom extrusion components can be weeks, which may not work for your schedule and budget.