Aluminum extrusion companiesspecialize in manufacturing custom parts out of aluminum. There are many benefits to using aluminum, including its light weight, strength, and durability. Working with an extrusion company can help you create parts that are tailored precisely to your needs.

Here’s how you can make the most of these companies and get the most out of your investment.

Research Companies Before You Buy

The first step is to research different top aluminum extrusion companies before you decide which one to work with. Look into their experience in the industry, reputation among customers, and overall quality standards.

It’s also a good idea to read customer reviews and ask for references from previous clients that have similar requirements to yours. Doing your due diligence will ensure that you find a reputable company that produces quality products.

Choose Materials Carefully

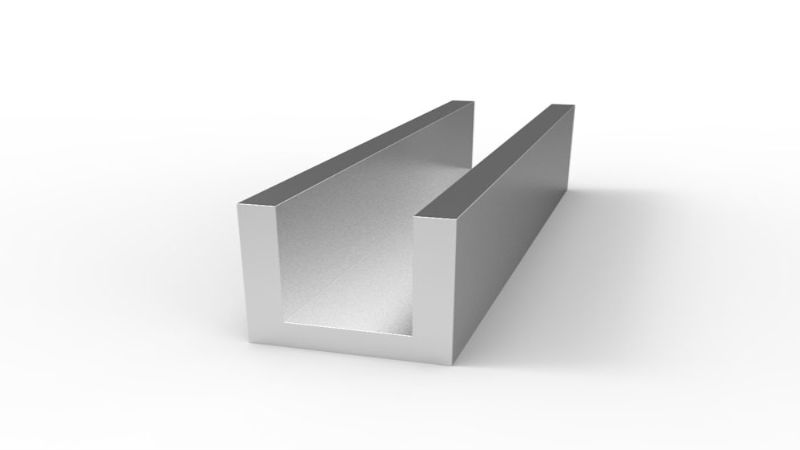

Aluminum is a versatile material that comes in a variety of grades and alloys, so it’s important to choose the right one for your project. Aluminum extrusions come in 6063-T5 (standard), 6061-T6 (structural), and 6082-T6 (marine grade).

Each type of alloy has its own unique properties, so it’s important to consider which one best meets your needs before making a purchase. Your aluminum extrusion company should be able to provide guidance on which alloy will work best for your project requirements.

Understand Your Design Requirements

Finally, it’s essential that you understand your design requirements thoroughly before working with any aluminum extrusion companies. Make sure that you have clear specifications for size, shape, strength, and other characteristics before placing an order for aluminum extrusions.

Having precise specifications will give the manufacturer a better understanding of what kind of product they need to produce for you and ensure a successful outcome when all is said and done.