There are different options in transformers that are used in electronic equipment, including in radios and speaker systems and other types of highly sensitive electronics. The most common choice is a toroidal transformer, and these can either be off-the-shelf models, or they can be custom designed and manufactured to meet the specific needs of the component or system.

For many OEMs, the standard options in toroidal transformers are not a good match for their current application. In these cases, working with a company to design and manufacturer custom toroidal transformers is the solution. This allows the OEM and the custom manufacturer to work together to ensure the transformer meets the needs of the system as well as any applicable standards and regulations for domestic and international applications.

Customizing for Size

One of the key reasons for OEMs to require custom toroidal transformers is to meet specific size requirements in a system. The smaller the electronic systems get, the more challenging it is to use standard sized components.

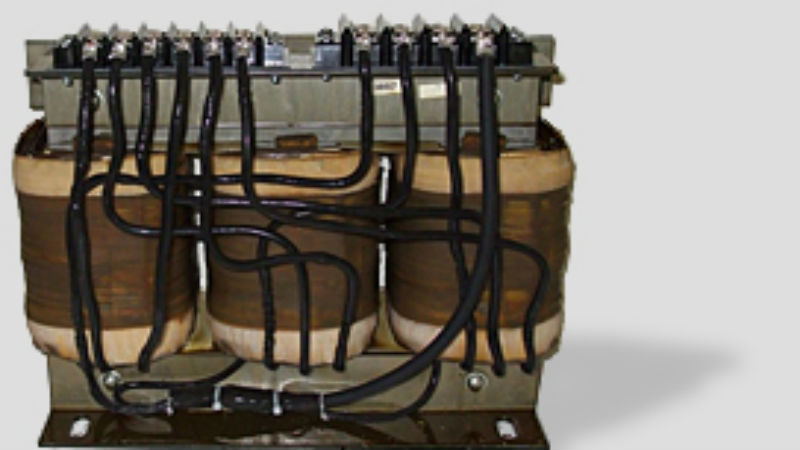

In the shape and design of the toroidal transformer, the actual physical dimensions of the core are not critical; rather it is the winding and the uniformity of the winding that is essential. The donut-shape allow significantly more windings that a straight core would provide, which means they can be designed to easily fit into very small physical space in a system.

Additionally, and this is important in complex systems, the donut-shape of these toroidal transformer combined with tight windings eliminates the issues with the electromagnetic radiation release which is common with other types of transformers.

To the OEM this means that custom toroidal transformers can be smaller and also installed in locations close to other sensitive components in the system without the need for additional shielding or modifications of the design.