For fabricating parts, or for designing specific types of items such as aluminum frames, workstations, office fixtures and furniture, retail display areas or other types of components, a simple, effective and easy option is always best. T channel, which may also be called T slot, offers the perfect system for effective fabrication and installation with minimal technical and skill level required.

In essence, the T channel systems can include both standard T slot components or they can be custom extruded for your particular needs. For OEM companies, there may be a need to choose a specific custom form for the T slot system, while for other types of fabrication a standard shape and size may be the best option.

Components

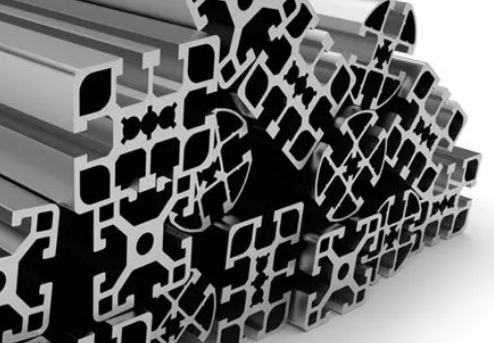

Within any T slot system, there will be a range of different components. This will include the actual T channel, or the long, straight components that are used to form the shape and the frame of different items.

Additionally, there will be corner brackets, hardware components and fasteners that are all designed to work with each other as well as the channel. The result in a system that will easily go together to create just the look and functional design required.

Most of the standard T slot systems will include all the components for right angles and basic design shapes. For unique applications or prototypes, working with an aluminum company that can provide the shapes and components required will be an essential consideration.

Strength and Durability

It is critical to keep in mind that the ease of fabrication and lightweight construction of aluminum T slot systems is not a compromise with regards to strength. In fact, these systems can be superior to welded components because they are faster to put together, there is less waste and there are fewer issues with using these fabrications in different working environments.

Naturally corrosion and rust resistant as well as non-magnetic and non-sparking, items made using this technology are superior over welded carbon steels or even the use of stainless steel.

It is important to consider the cost of custom extrusions versus standard extrusions in larger fabrication projects. With custom extrusion, there will be more initial cost while with standard T slot systems the product, including channel, will be standard sized and available from top aluminum suppliers. This keeps the price lower, which may be an important consideration for more than just a small, one-time type of fabrication need.